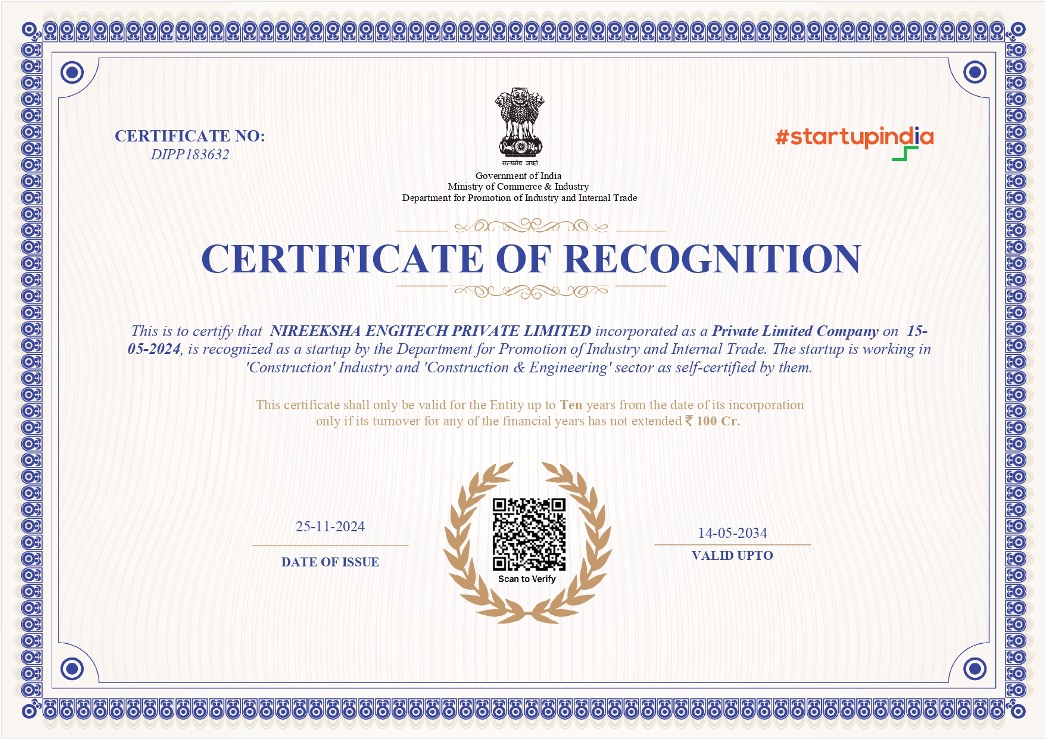

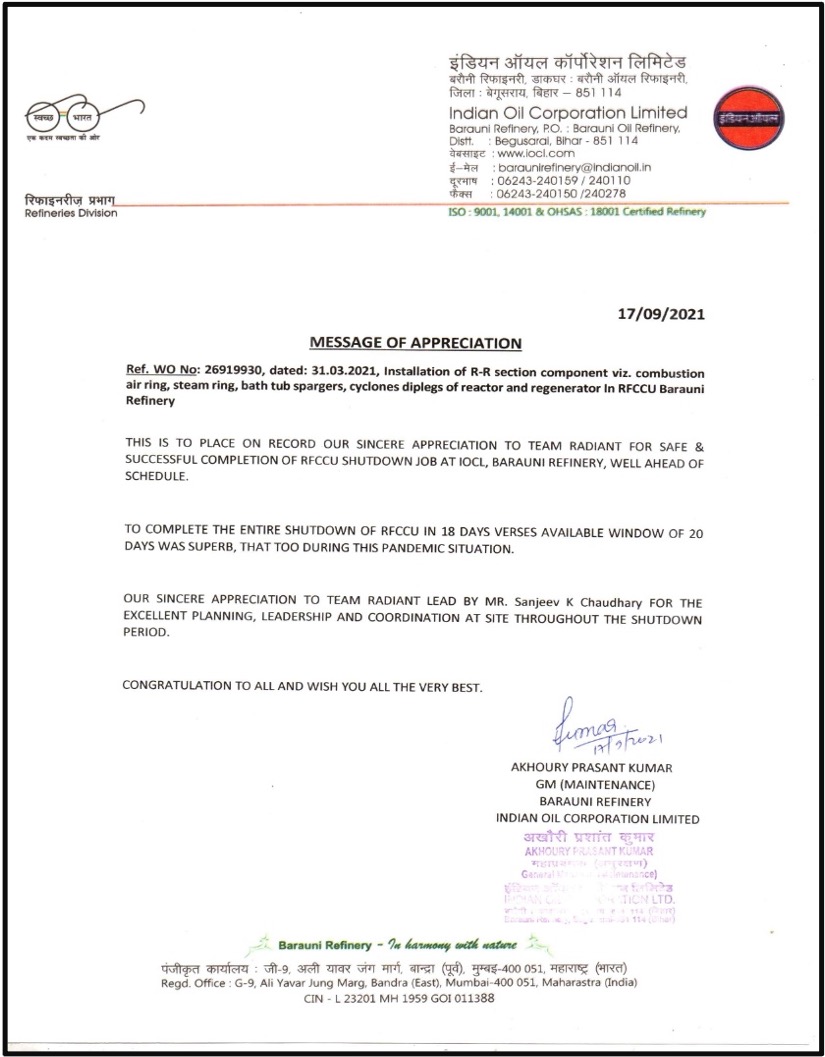

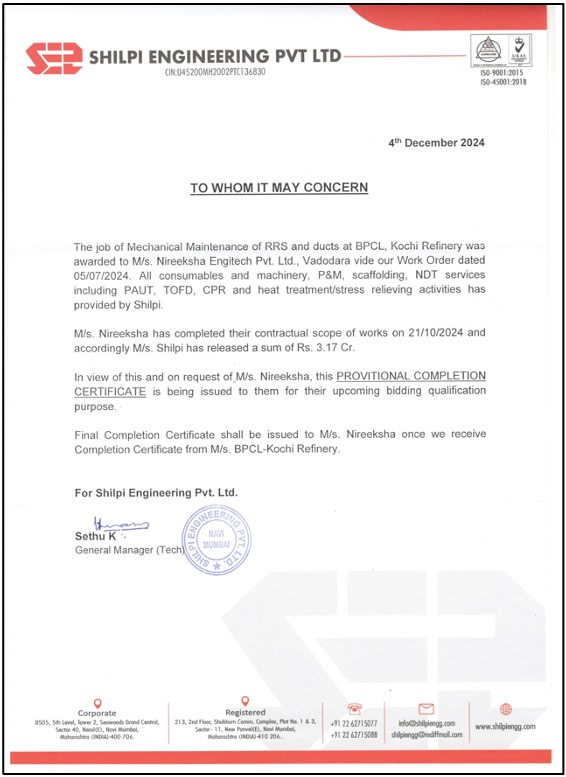

Nireeksha Engitech Pvt. Ltd. is a dynamic and innovative engineering firm specializing in turnaround, maintenance, and project execution for the refinery, petrochemical, and fertilizer industries. With a proven track record, the company has successfully completed over 270 turnaround jobs, including more than 38 specialized projects such as revamps and turnarounds of the Reactor: Regenerator System (RRS) in RFCCU (Residual Fluid Catalytic Cracking Unit), PFCCU (Propylene Fluid Catalytic Cracking Unit), and ZFCCU (ZSM-5 Fluid Catalytic Cracking Unit). This extensive experience has earned the trust and satisfaction of prestigious clients, including IOCL, BPCL, HPCL, and RIL across PAN India. Formerly known as NEPL, Nireeksha Engitech Pvt. Ltd. was officially upgraded on May 15, 2024, expanding its global service reach from Nireeksha Inc. following the successful completion of multiple turnaround and project jobs. The company's workforce has grown significantly, scaling from 200 to 1600 skilled personnel to cater to end users such as RIL Jamnagar, IOCL Panipat Refinery, and IOCL Bongaigaon Refinery, reinforcing its commitment to excellence and reliability in the industry.

Turnarounds, maintenance & revamp services

Heavy erections services

Piping, fabrication & erection services

Fabrication & erection of tanks, structural job

Emergency breakdown maintenance

Project works

Allied NDT services

Manpower supply services

General maintenance and cleaning of the RRS System, including the reactor, regenerator, orifice chamber, standpipe, co-boiler, fractionators column, and heaters. Key tasks included replacing four reactor cyclones, repairing the LDD gas tube, replacing the regenerator air grid, standpipe, expansion bellow, and regenerator nozzle. Additional work involved reinforcing the kicker box support, upgrading the vapor line from 28” to 34” dia, decoking and replacing heater tubes, and renewing hex mesh and refractory lining.

Fabrication, supply, and replacement of the stripper section with an internal riser, two regenerator primary cyclones with transfer ducts, air rings, and the regenerator catalyst lift line. Work included removal, cutting, rigging, and welding, completed with a workforce of ~850 in 28 engineering days.

The job involved the cutting and dismantling of the Orifice Chamber using a 600 M.T lifting crane, following the removal of allied accessories,

spring supports, and connected piping and structural elements. The scope also included the fit-up and welding of a new Orifice Chamber, along with

associated Non-Destructive Testing (NDT) activities. Subsequent tasks included re-fit-up, alignment, and final welding.

The entire job was successfully completed in 16 days, two days ahead of the scheduled 18-day timeline.

Maintenance of heat exchangers, columns, vessels, fin fan coolers, and other equipment, carried out with a total workforce of ~1100.

Replacement of the regenerator dome, primary and secondary cyclones, and maintenance of the reactor, regenerator, and shell. Tasks included repairing the stripper section, replacing stripper packing, all 12 optimix nozzles, bellows, and the transition zone. Also involved column and COB system maintenance, completed with ~1000 manpower.

Handling and replacement of a 6MT flare tip assembly at a 100M elevation, including erection and dismantling of a 600MT crawler crane. Completed successfully in 8 engineering days with ~150 manpower.

Founder

"Nireeksha aims to remake the modern world, not just through skills but through loyalty. From the layman to the highly skilled, the world requires something from everyone, and Nireeksha steps in to fill the bridge. Nireeksha will be to the world of steel what evolution is to humanity."

Vadodara, Gujarat, India